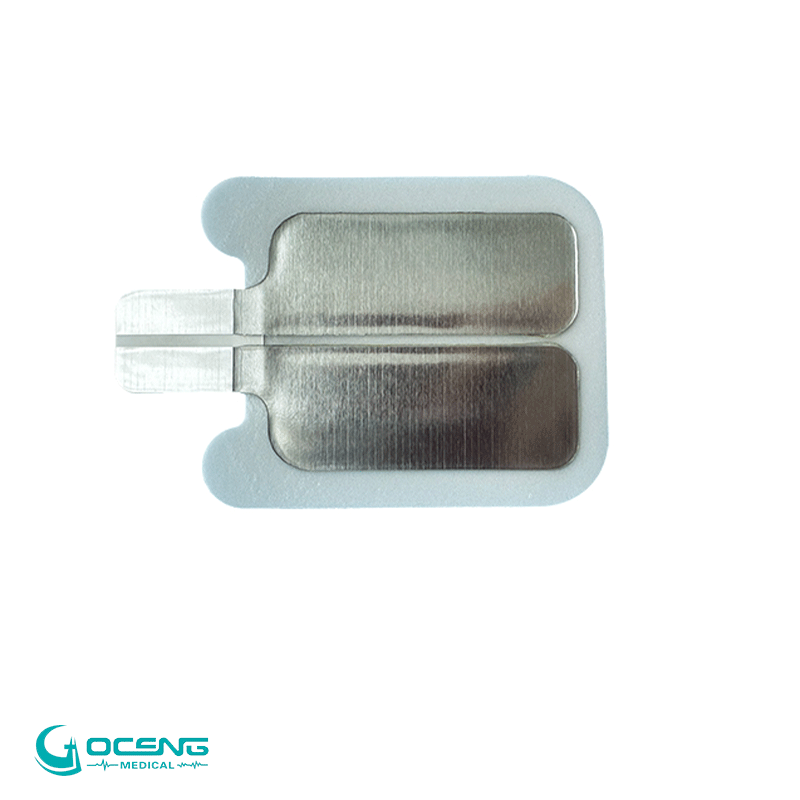

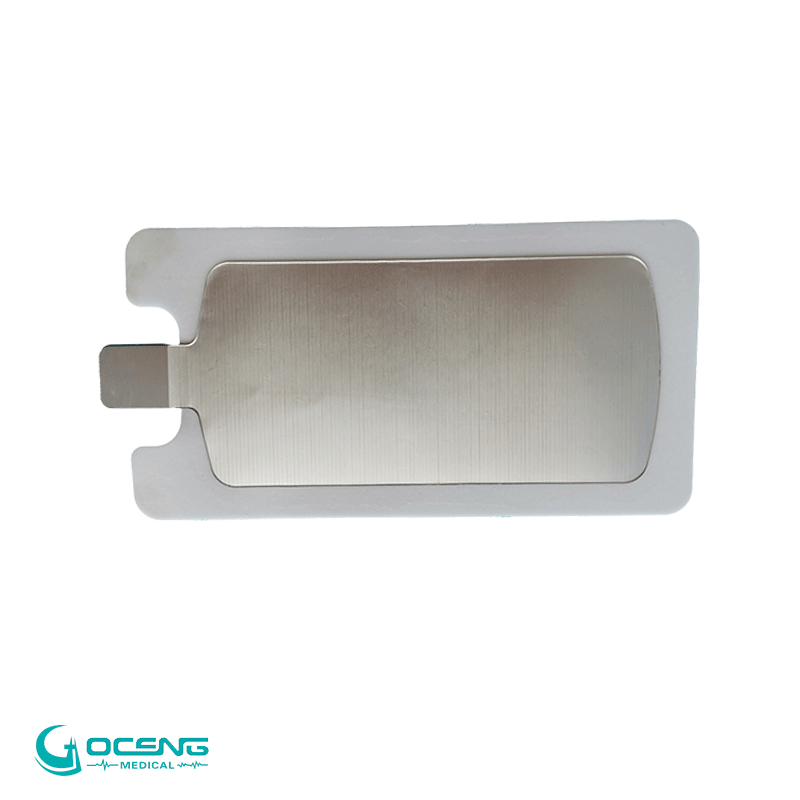

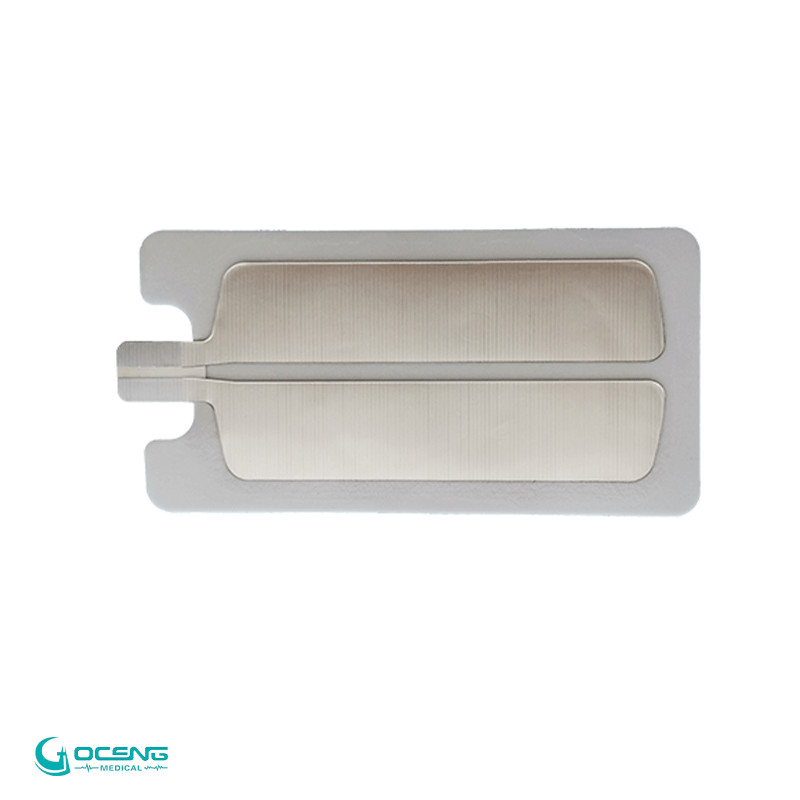

Tin film can be an important material in the context of Automated External Defibrillator (AED) pads. AED pads are designed to deliver electrical shocks to the heart in cases of sudden cardiac arrest, and the materials used in their construction can impact performance, safety, and comfort.

Key Aspects of Tin Film in AED Pads

-

Conductivity: Tin is a good conductor of electricity, which is crucial for the effective transfer of the defibrillation shock to the patient's body. Tin films can help ensure that the electrical signal is transmitted efficiently.

-

Biocompatibility: The materials used in AED pads must be safe for contact with human skin. Tin oxide, for instance, can be modified to enhance biocompatibility, reducing the risk of skin irritation.

-

Durability: Tin films can provide a protective layer that enhances the durability of AED pads, helping them maintain performance over time, especially in varying environmental conditions.

-

Adhesion Properties: The design of AED pads requires them to adhere firmly to the skin to ensure proper contact during defibrillation. Tin films can contribute to the adhesive properties of the pads.

-

Sensing Capabilities: In some advanced AED systems, materials like tin oxide can be used in sensors that monitor heart rhythm, allowing the device to assess when defibrillation is necessary.

-

Research and Development

Ongoing research may focus on optimizing the properties of tin films for use in AED pads, including improving conductivity, enhancing comfort, and increasing the shelf life of the pads. Goceng medical team uses the 0.05mm PURE tin film to cover with hydrogel to produce the AED electrode , there are several advantages of this technology :

1. High Electrical Conductivity:

- Tin is an excellent conductor, which ensures efficient transmission of electrical impulses during defibrillation, leading to more effective shocks.

2. Biocompatibility:

- Tin oxide and modified tin materials can be biocompatible, reducing the risk of skin irritation or allergic reactions when the pads are applied to a patient's skin.

3. Corrosion Resistance:

- Tin films are resistant to oxidation and corrosion, which helps maintain the integrity and performance of the AED pads over time, especially in varying environmental conditions.

4. Lightweight:

- Tin films can be very thin and lightweight, contributing to the overall portability and ease of use of AED devices.

5. Improved Adhesion:

- Tin can enhance the adhesive properties of AED pads, ensuring that they stay in place during use, which is crucial for effective shock delivery.

6. Temperature Stability:

- Tin exhibits good stability across a range of temperatures, which can be beneficial for AED pads that may be stored in diverse environments.

7. Sensing Applications:

- Tin oxide can be used in sensors that monitor heart rhythms, enhancing the functionality of advanced AED systems by allowing them to determine when defibrillation is necessary.

But Tin is relatively abundant and high expensive compared to some other conductive materials, potentially increasing production costs while maintaining quality. Let us know if you want to custom your electrodes by special material --tin film .

Check more at : www.gocengmed.com