The newest AED (Automated External Defibrillator) pads are designed with advanced materials to enhance conductivity, adhesion, and patient safety.

The main materials :

1. Conductive Gel

- Material: Hydrogel

- Purpose: Ensures optimal electrical conductivity and maintains strong adhesion to the skin, even in high-moisture or sweaty conditions.

- Improvement: Newer hydrogel formulations provide better skin contact with reduced irritation.

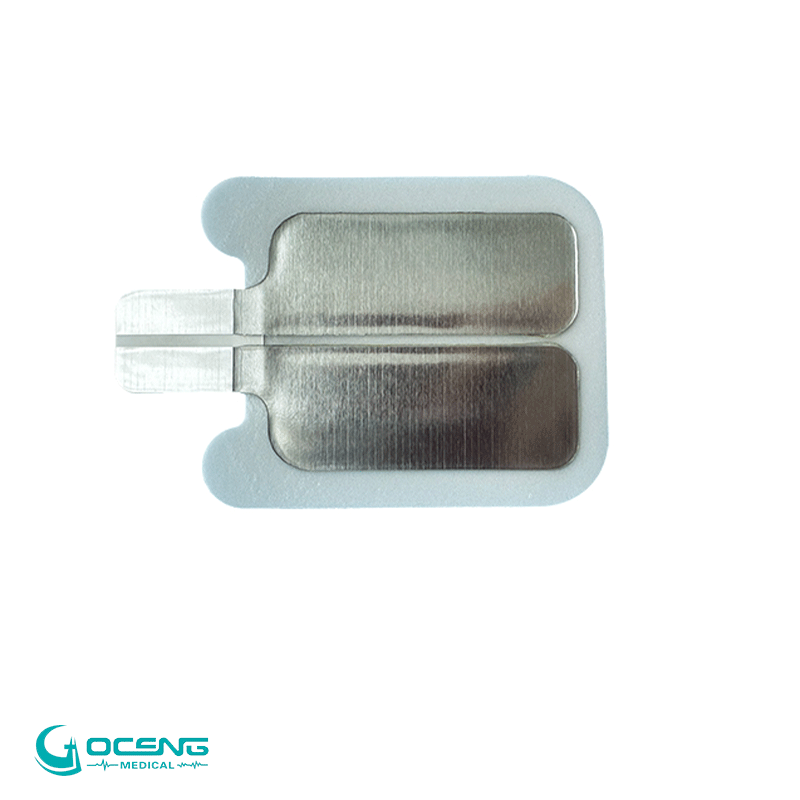

2. Electrode Layer

- Material: Carbon , Silver-silver chloride (Ag/AgCl) or Tin

- Purpose: Conducts electrical signals efficiently and provides a stable connection for ECG monitoring.

- Improvement: Some newer pads feature multi-layered electrodes for more accurate shock delivery and better signal detection.

3. Adhesive Backing

- Material: Medical-grade adhesive film (Polyurethane or Silicone-based)

- Purpose: Ensures the pads stay in place during CPR or movement.

- Improvement: Newer adhesives are hypoallergenic and designed to maintain strong adhesion without damaging the skin upon removal.

4. Substrate Layer

- Material: Non-woven fabric or flexible polymer (Polyethylene or Polyurethane)-Foam

- Purpose: Provides structural support while remaining flexible for easy application.

- Improvement: Some modern AED pads have ergonomic designs with pre-curved backing to match the body’s contours.

5. Connector & Wiring

- Material: Copper or aluminum wiring with insulated sheathing

- Purpose: Transfers electrical impulses from the AED to the pads efficiently.

- Improvement: Some new AED pads feature integrated CPR feedback sensors to assist rescuers in maintaining the correct compression depth and rate.

6. Protective Packaging

- Material: Foil bag or PP -sealed pouches

- Purpose: Extends shelf life by protecting pads from air, moisture, and contaminants.

- Improvement: Newer packaging includes visual indicators for expiration and readiness status.

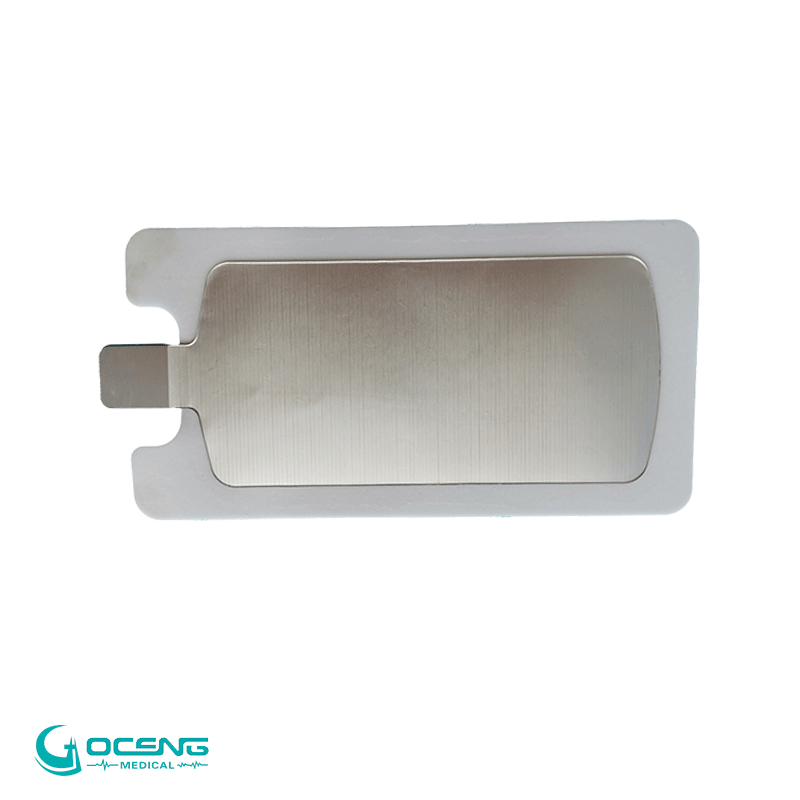

The thickness of the tin layer in AED (Automated External Defibrillator) pads can significantly impact their performance, conductivity, durability, and patient safety. How different thicknesses of tin in AED pads affect their functionality:

1. Electrical Conductivity

- Thicker Tin Layer:

- Provides better electrical conductivity as it offers a more stable path for the defibrillation shock.

- Reduces resistance, ensuring more efficient energy transfer.

- Thinner Tin Layer:

- Higher resistance may lead to energy loss, potentially reducing the effectiveness of the shock.

- Could cause hot spots that might increase the risk of burns on the patient's skin.

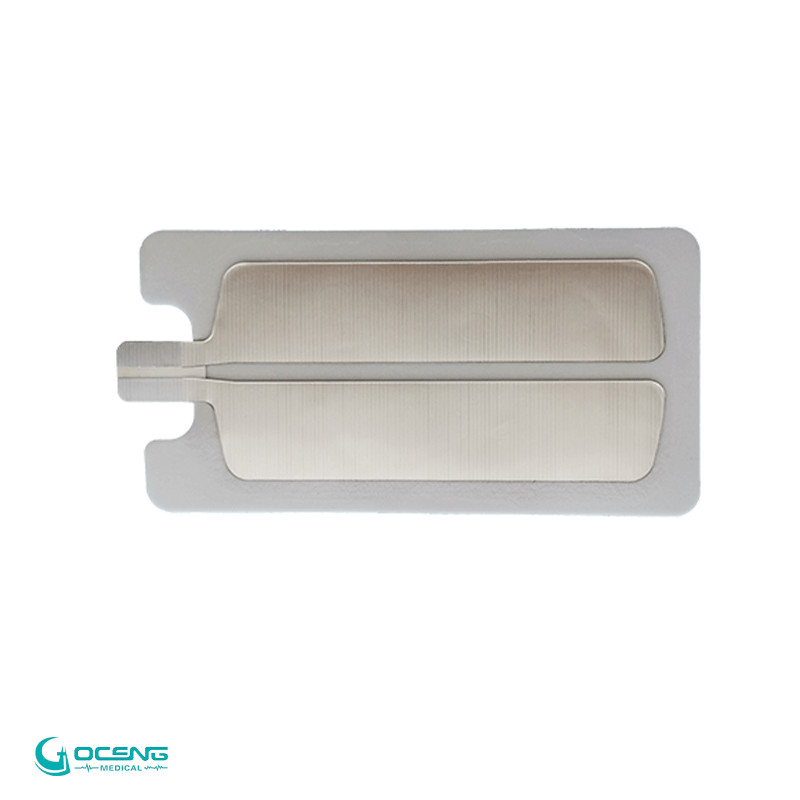

2. Flexibility & Conformability

- Thicker Tin Layer:

- More rigid, which may reduce flexibility, making it harder to contour around the patient’s chest.

- May affect adhesion, leading to poor skin contact and decreased effectiveness.

- Thinner Tin Layer:

- More flexible, allowing the pads to conform to the patient's body better.

- Ensures even distribution of energy and reduces gaps between the pad and skin.

3. Durability & Shelf Life

- Thicker Tin Layer:

- More resistant to corrosion and wear over time, improving longevity.

- Less likely to tear or degrade, making it ideal for extended shelf life.

- Thinner Tin Layer:

- More susceptible to oxidation or degradation, especially in high-humidity environments.

- May have a shorter shelf life compared to thicker versions.

4. Heat Generation & Safety

- Thicker Tin Layer:

- Distributes heat more evenly, reducing the risk of localized burns.

- Provides a safer shock delivery, especially for patients with sensitive skin.

- Thinner Tin Layer:

- Can cause uneven heating, leading to potential skin burns at high-energy shock levels.

- May overheat faster, reducing safety during multiple shocks.

5. Signal Quality for ECG Monitoring

- Thicker Tin Layer:

- Ensures a stable and clear ECG signal, reducing signal noise during analysis.

- Helps AEDs detect arrhythmias accurately before delivering a shock.

- Thinner Tin Layer:

- More prone to signal distortion, which could affect AED decision-making.

- Might interfere with CPR feedback sensors in advanced AED models.

Goceng medical manufactures several types thickness of tin AED PAD : 5C / 6C / 7C tin ,the thicker one the better for production and usage .

Let us know which type you want ?

Check more at : www.gocengmed.com